eLIM

Tablet Sorting SystemProduct Info

Learn more about Prodieco’s Elim

Product Gallery

Take a closer look at the Elim’s features

Download Brochure

Click here and download your copy today

Contact Sales Team

Call us now. We will be happy to help

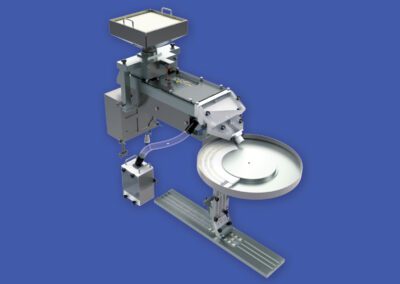

Introducing the groundbreaking Elim machine by Prodieco, designed to address challenges faced by pharmaceutical companies due to broken tablets causing disruptions in feeding systems and downtime.

The Elim employs a mechanical vibratory system that efficiently sorts broken products before they enter the tablet feeding system. This versatile solution can be seamlessly integrated into various machine types and multiple sites, enhancing Overall Equipment Efficiency (OEE) for blister packaging lines.

With its inline capability, the Elim significantly reduces setup time compared to labour-intensive offline sorting systems. Implementing the Elim system translates to substantial cost savings, minimising product waste, and boosting operator morale in your operations. Elevate your packaging line performance with the innovative Elim machine from Prodieco.

A Unique Sorting Solution That Eliminates Defective Products While Boosting OEE And Maximising Production.

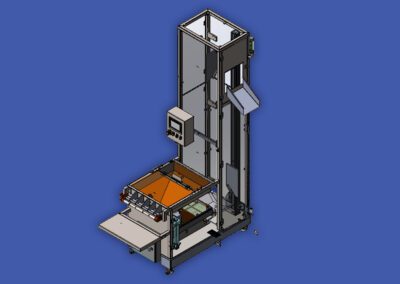

VERSATILE SYSTEM APPLICATIONS: INLINE & OFFLINE SORTING SOLUTIONS

Auto Weighing Scale Integration

Precise weight programming for sorting, with automatic shut-off for container switching

Explore the Functionalities of the elim System:

Operational Mechanism: The elim system operates under PLC control, incorporating a gate mechanism to regulate tablet flow. With product channel widths of 300mm or 400mm, the throughput varies based on blister machine specifications and tablet geometry.

Efficient Throughput: Achieve impressive throughput rates of up to 4-5kg/min. The vibratory drive unit guarantees a single-layer sieving process, ensuring optimal efficiency.

Adaptable Sieve Plates: Dedicated, product-specific sieve plates are thoughtfully designed for quick and seamless changeovers, streamlining the process.

Enhanced Rejection Capability: The elim system’s core strength lies in its ability to reject broken, clumped, and capped tablets. This proactive rejection process eliminates micro-stops, subsequently boosting Overall Equipment Efficiency (OEE) for blister packaging lines.

Precision Quality Control: Prodieco’s meticulous quality control measures confirm that all tablet particles smaller than 75% of the tablet size are consistently rejected 100% of the time.

Experience the elim system’s intelligent design and advanced features, ensuring smoother operations and optimised performance for your packaging lines.

Discover how to eliminate defective products and increase production.

-

Eliminate Expenses

-

Eliminate Broken Tablets

-

Eliminate Tablet Particles

-

Eliminate Tablet Twins

-

Eliminate Micro Stoppages

-

Eliminate Low Operator Morale